Forge 3 - Thermal Model and Thermocouple Selection

The objective of this project was to gain a detailed understanding of the heating conditions of our forge. The three key objectives of this project were to -

Identify any hot or cold spots in the forge that would impact the homogeneity of the heating environment

Determine any modifications needed to increase the efficiency of the base forge

Select a thermocouple and its placement within the forge for the most pertinent temperature

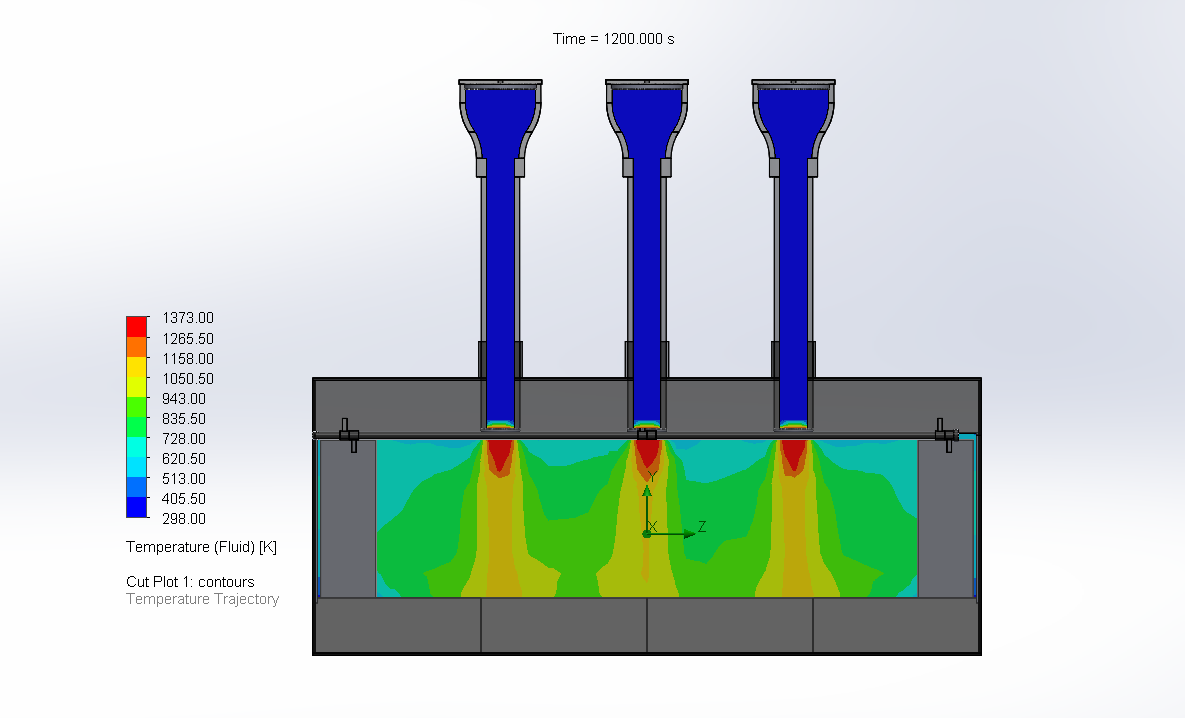

Candice S. and Geneva L. from our forge sub-team collaborated to meet the deliverables of this project. To attempt to thermally model the propane burner flame, the boundary between the chimney and the forge box was defined to be a porous material with a constant internal temperature corresponding to that of a propane flame. This porous boundary allowed for gas to flow through and become heated. Once the base case of heat flow through the forge was modelled, two fire bricks were then placed in the openings of the forge to increase the thermal efficiency.

Simulation 1: All Burners Base Model

Simulation 2: Middle Burner Base Model

Simulation 3: All Burners with Firebrick Doors

The thermocouple selected is the Omega Type K High Temperature Low Drift TC Probes in conjunction with the Inkbird ITC-100VH PID Temperature Controller. These products were chosen for their high working temperature (up to 1335 °C), low cost, and long lifespan. The thermocouple will be inserted through the back forge wall and sit just above the metal being forged. This will allow accurate reading of the flame temperature that heats the blade.